Our plant is located 30 miles west of Chicago and is less than one mile to the I-90 interchange. We occupy 60,000 square feet and are capable of expanding by an additional 26,000 square feet. Spring manufacturing plants need to have flexibility in their floor plans. We have the flexibility to add machines, move spring coiling and support equipment in and out as jobs change. Patrick has CNC coilers and numerous support equipment producing millions of springs for OEM’s around the world.

Coiling Department

Our coiling department is comprised of state-of-the-art technology and our dedicated team of artisans employ this technology of the 21st century to its maximum potential. Spring coiling is part science and a bigger part art. CNC technology is imperative to compete in the global marketplace.

CNC technology offers our customers the highest quality available. The CNC coiler with looping station produces your parts with the highest precision and is controlled by servo monitors. The servo controlled coiler is 4 axis and has 8 cam action slides.

- CNC "State-of-the-Art" Spring & Wire Form Coiling Equipment

- CNC Spring Coilers and Formers

- Mechanical Spring Coilers and Formers

- High Speed (popcorn) Spring Coiling Department

- Proprietary Equipment and Technology

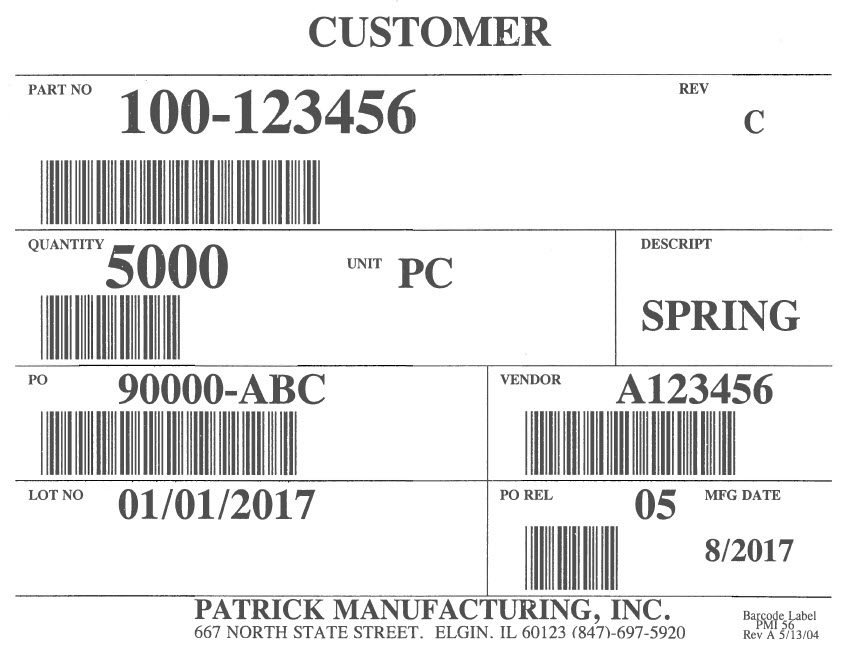

Shipping Department

Our shipping department offers the latest in bar coded labeling, shipping manifests and invoices. Our barcode labeling system utilizes language 39 and will reduce inventory errors, handling costs and optimize your tracking goals. Standardized quantities are determined to support your needs when applicable. The proper packaging is based on numerous factors. The parts' design, weight, pieces per container and EAU. We will provide solutions for efficiency while minimizing wasteful packaging to keep disposal handling or costs down. Available packaging options include fiber drums, gaylords, standard cartons, custom cartons, tacky boards, wires, bags, etc. We process PO's and manage planning and scheduling via Supplier Portals and can provide advanced shipping notices (ASN) and UPS notice and tracking numbers when your products ship.

Finished Goods and Raw Material

Our springs and wire forms are produced per your purchase order and/or based on your EAU quantities. Our finished goods are prepackaged and ready to be pulled when your schedule dictates allowing us to ship at a moment’s notice accommodating fluctuations in your demands. Our on-time delivery performance percentage is 99%. Patrick Manufacturing is located in a market area where material suppliers are nearby and wire can be recieved the very next day or sooner. Because everthing is custom, material is bought per job for most instances. For higher volume and/or common sizes direct truckload mill buys are also utilized for those high volume customers to get the most economical production prices possible.

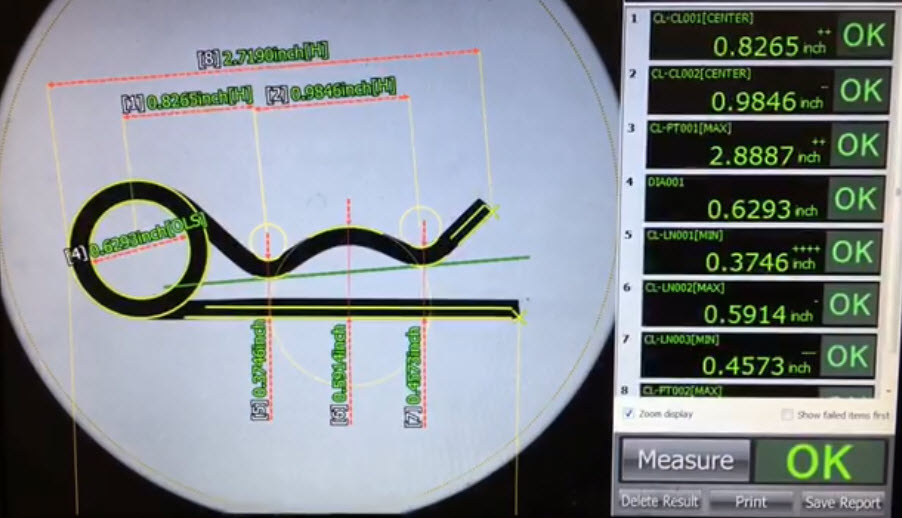

Quality Assurance

A comprehensive quality management system ensures that your quality requirements are met. Probe sensing is used to support in-process inspection ensuring quality requirements are met. This attention to detail allows your customers to be assured that their projects are in capable hands.

Our Happy Crew

Pattie Lane - Sales

Susan McGrail - President

Judy Lang - Shipping Manager

Patrick McGrail - Founder