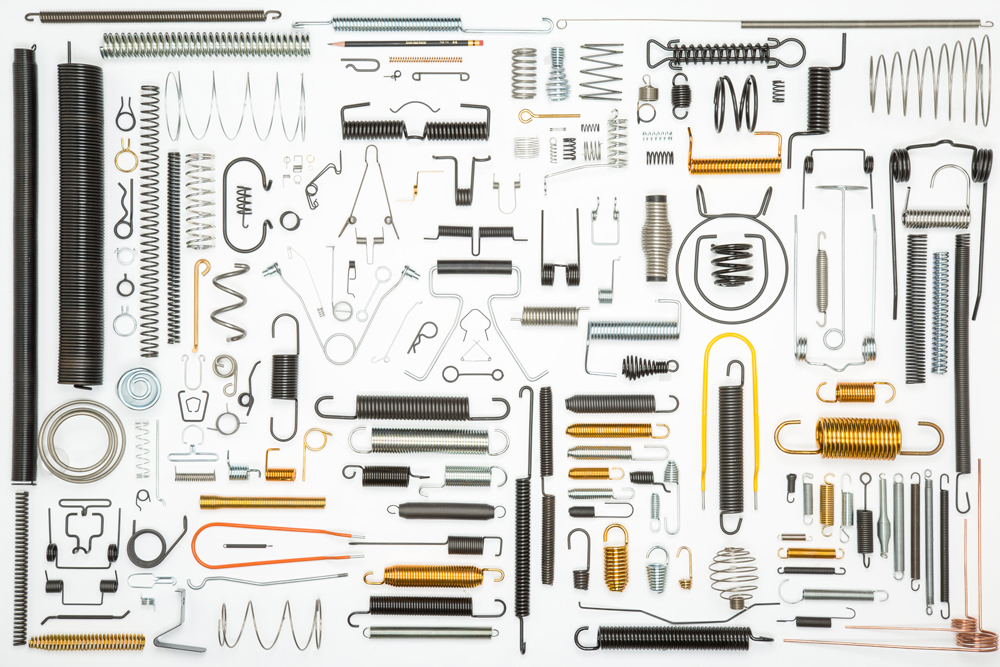

Springs

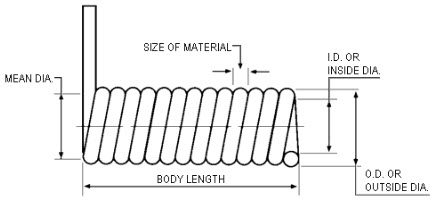

Our custom springs are manufactured on equipment that can use the following range of wire sizes:

- Compression Springs up to .187" wire diameter

- Extension Springs up to .236" wire diameter

- Torsion Springs to up to . 236" wire diameter

- Double Torsion Springs up to .236” wire diameter

- Magazine Springs up to .195” wire diameter

- Drawbar Springs up to .195” wire diameter

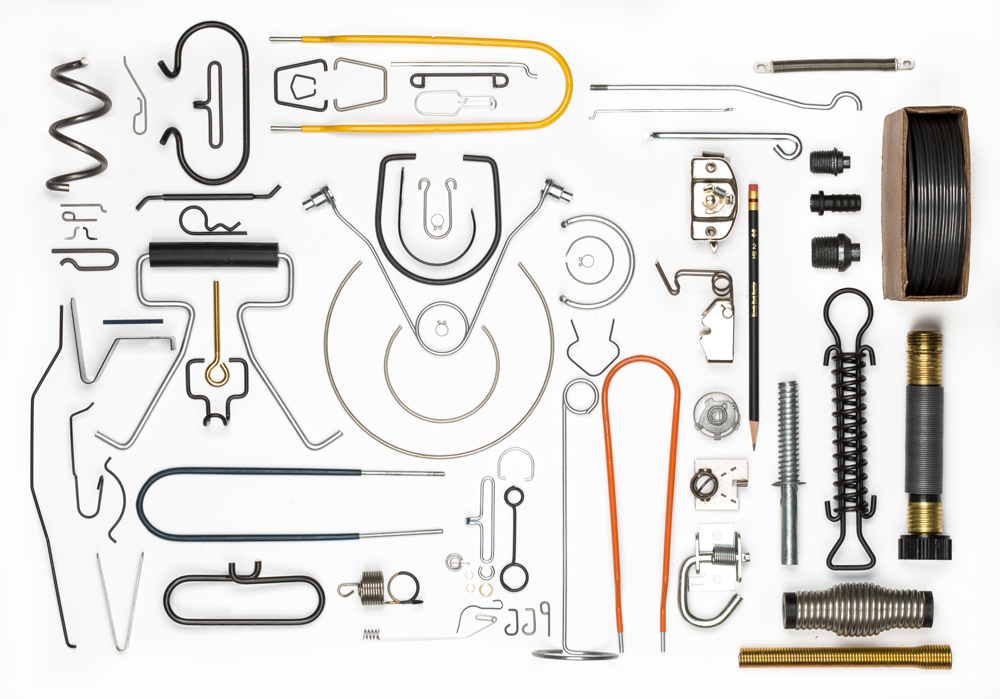

Wire Forms

Our equipment can produce wire forms and straighten & cut parts with the following wire sizes:

- From .012” to .250” wire diameter.

- Based on EAU and design, one of the following production methods will be utilized:

- Secondary Department: .020" -.250” wire diameter

- CNC Department: .020" -.236” wire diameter

Flat Springs & Specials

Strip stock for flat springs is manufactured to your specifications utilizing fourslide machine. Great for high volume demands and offers lower tooling costs. Straighten & Cut flat springs can be manufacturerd in two different production methods. We can ensure proper match of machinery to your design, material and usage for the most economical production method.

- Strip Material Min/Max:

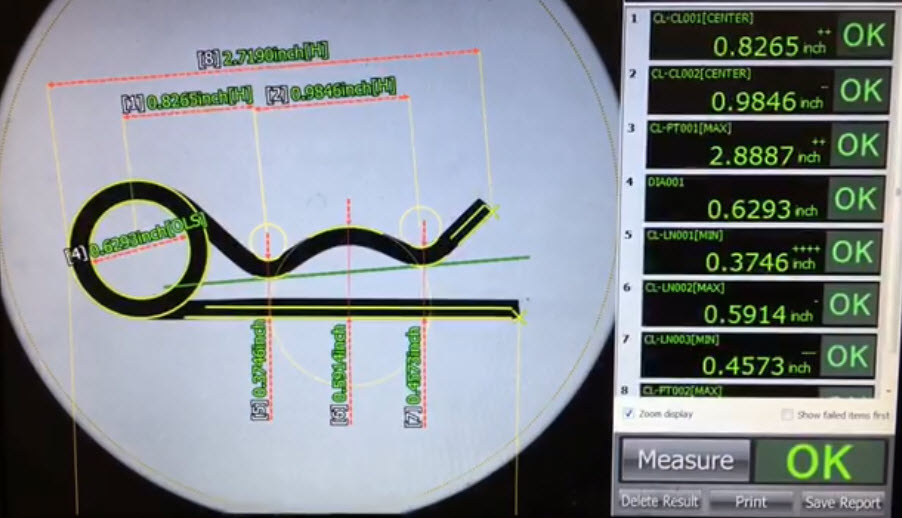

Quality

A comprehensive quality management system ensures that your quality requirements are met. Probe sensing is used to support in-process inspection ensuring quality requirements are met. This attention to detail allows your customers to be assured that their projects are in capable hands.

Order Process/Cost Analysis/Free Services:

- Email your blueprint to Patrick Manufacturing for pricing

- We can work with your engineers to provide design assistance as it relates to the application or other coiling or forming data parameters

- Cost reduction analysis of new or existing jobs are always offered

- Receive your quote and place your order

- Pre-production samples free with production order

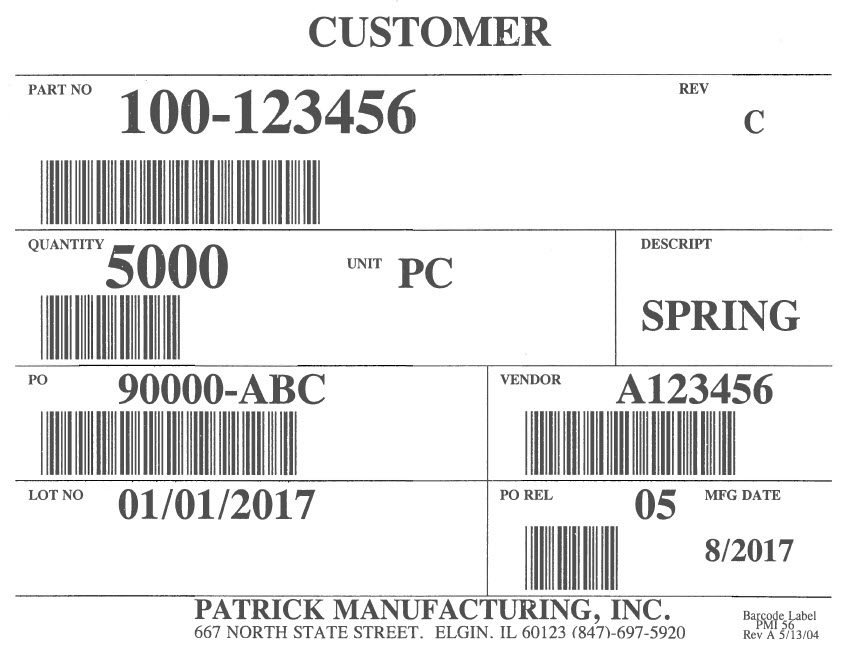

- Bar coded lables, manifests, and invoices

- ASN provided per customer's request (Advanced Shipping Notice)

- UPS shipment tracking number and notices given per your request

- Supplier Portal management - We adhere to your automated direction for PO, planning and shipping schedule.

- Design collaboration with your engineers to achieve your goals and solve problems

In House Capabilities

Our excellent in-house tooling expertise for both coiling, secondary departments and stamping tooling offers great flexibility for customers and their scheduling demands. We offer:

- CNC and mechanical spring coilers and formers

- High speed (popcorn) spring coiling

- Fourslide Machine for strip straighten & cut

- Latest technology in inspection measuring equipment

- Just-in-time delivery

- PPAP certifications upon request

- Bar coded labeling, shipping manifests and invoices

- Cost effective packaging of all our products